Products

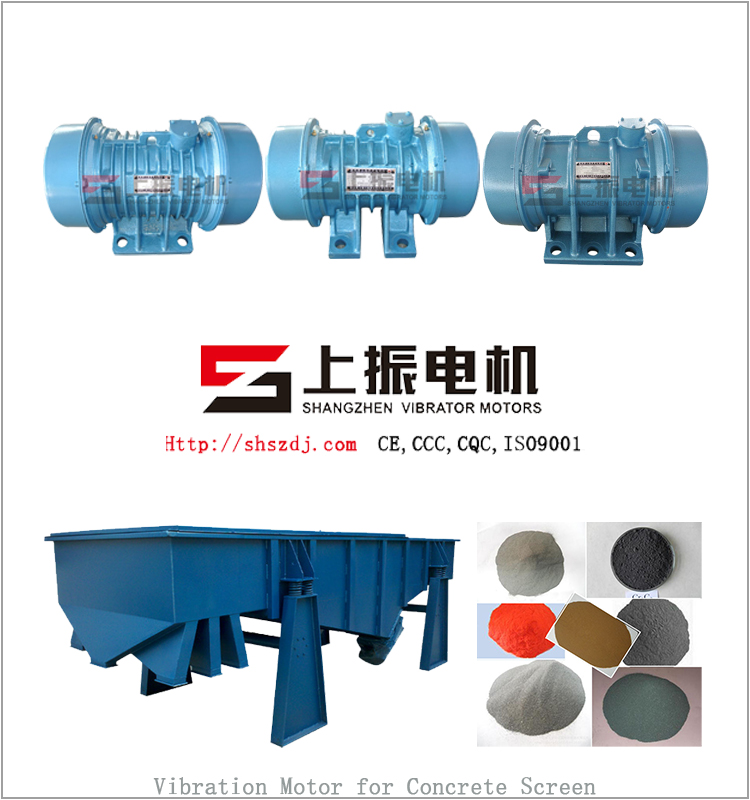

Concrete vibrating screen table motor

location:Home > Product Center... > YZO Vibrator Motors... > Concrete vibrating s...Concrete vibrating screen table motor

Products Outline:

Company Introduction:

Shanghai SHANGHZNE Vibrator Motors Co., Ltd is a professional vibrator motor manufacturer with the whole of study, producing, sales, service. As a leader in the vibrator motor industry, we have been focusing on the vibrator motors industry for almost 30 years, with professional and hard work, we have won comprehensive advantages in human resources, technology, market, brand and other parts. We have many customers all around the world, EIRICH, Weir Minerals, Baosteel, Anshan, etc.

In many years, focusing on vibrator motor industry and being the leader are always ou pursuing. Honesty, high quality product, good service, steady supply and wincooperation are our marketing faiths, we have won high comments from many customers both inner and oversea.

Working Environment

Installation and use

1. Conditions of use

(1) The temperature of the environment needs to be under 40 centi degrees, and the power use should be reduced if more than 40 centi degrees.

(2) The altitude should not exceed 1000 meters, if it is more than 1000 meters but not more than 4000 meters, each increased to 100 meters, the value of temperature rise should be decreased to 0.5 centi degree;

(3) Power supply: three phase 380V, single phase 220V, frequency 50HZ;

(4) The way of work: SI (continuous);

(5) The rated temperature of the vibration motor is 65;

(6) The excitation force of the main engine must not exceed the data on the vibrating motor nameplate, otherwise the excitation force can be reduced.

(7) The use of environment should not be conductive dust, inflammable, explosive and corrosive gas, otherwise the selection of explosion-proof vibration motor.

2. Installation

The cement sieves should be installed above the packing storehouse, and the damping rubber pad should be added to the junction of the upper port of the packing bin so as to play the role of dustproof and vibration release. The compressed flat steel under the vibration motor is loosely installed for transportation. It must be removed before the machine is opened. Cement sieve and vibration motor fastening bolts and anchor bolts should be stable and reliable, with check nut or spring washers and locking to prevent loosening.

3. The adjustment of exciting force

The adjustment of the exciting force: the shield of the two ends of the vibration motor is unloaded and the eccentric block at the ends of the two ends is leaked out. When adjusting, the eccentric block at both ends should be adjusted in the same direction with the same scale value. Even if the required line of excitation force on the eccentric block is aligned with the positive axle head scale line, the synchronous excitation force at both ends should be guaranteed. Before the factory has been adjusted, the users can adjust themselves if they have special requirements, and re - fasten all the nuts after adjustment.

4. Operation and maintenance

Once the cement screen is accumulated for 100 hours, tighten the fastener (bolt) once every 24 hours, and run for 100 hours. The final reinforcement shall be tightened again. Often open the upper cover to observe whether there are residual impurities on the screen. If it should be removed in time to prevent network holes from blocking and affect production, and also to check whether the screen is damaged, if the screen should be replaced in time.

5. Maintenance and maintenance

The vibration motor run 1000 hours, bearing cleaning, replacement of grease, also must conduct regular maintenance, repair a three month overhaul once a year.

When we need to replace the screen, first release the pressure plate bolts, remove the upper cover and the rubber plate above, then we can reassemble the screen frame assembly outside the machine frame and reload it after changing the new network. When we need to replace the damping spring on the four corners below the screen, it is the same as the above steps.

Note: spring and other parts do not fall into the silo so as not to get stuck in the impeller of the packer. Therefore, when changing screen and spring, we should check the following protective nets, whether there is any damage to the care network, if we need to replace the protection net in time, we can prevent the spring and other parts from falling into the bin.

Products Parameters:

We have two logos for our vibration motors:

![]()

![]()

Download: