Applications

Conveyor Equipments

location:Home>Applications>Conveyor Equipments

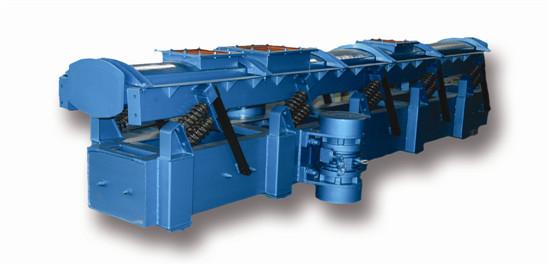

Vibrating conveyor is a continuous conveying machine that uses a vibrator to make the slot vibrate, so that the material in the slot is slid or move in a certain direction. Generally used for horizontal transport, the productivity is less than 150t/ h, the transport distance is less than 80m, and the productivity decreases with the increase of inclination. The excitation mechanism of some components, rotating relatively few components and simple structure, can transport all kinds of material, to the hot, flammable, toxic, dusty material closed transport, in the transport process can be completed at the same time screening, dehydration and cooling process. But it is not suitable to transport sticky materials. It is commonly used in chemical and building materials factories.

Structure:

An equipment that conveyed materials continuously with the help of vibration. It is mainly composed of the vibration exciter, the bearing tank, the main vibration spring and the frame. It can be used for all kinds of loose materials in horizontal, slow or vertical transport (rising along the spiral groove). In the process of transportation, screening, drying, dehydration, cooling, mixing and other processes can be completed at the same time. Materials with more dust and harmful components can be transported in sealed tanks. Its structure is simple, power consumption is small, and it has been widely used in mine.

1, conveying tank and balance underframe

The conveying tank (carrying body, tank body) and the balance under-frame (bottom frame) are two main components in the vibrating conveyor system. The transportation of materials, the main body of the inertial force balance frame, and reducing dynamic load to the foundation.

2. Vibration exciter

The vibration exciter is the power source of the vibration conveyor and the exciting force that produces periodic changes, so that the continuous vibration parts of the conveying groove and the balance chassis can be divided into mechanical, electromagnetic, hydraulic and pneumatic types. The magnitude of the exciting force directly affects the amplitude of the conveying tank.

3, the main vibration spring and the vibration isolation spring

The main vibration spring and the vibration isolation spring are the elastic elements in the vibrating conveyor system. The main vibration spring action: support conveying trough main vibration spring, usually installed obliquely inclined angle beta (vibration angle), its role is to enable the vibration conveyor near resonance point is appropriate, kinetic and potential energy of the system transformation, the effective use of vibration energy. The isolation spring function: support, and reducing load to the foundation or structure.

4. Guide rod

The role of the guide bar is to make the tank and the bottom frame perpendicular to the center line of the guide bar to make relative vibration, which is connected to the tank and the bottom frame through the rubber hinge.

5, feeding device and discharging device

Feed and unloading devices are used to control the flow of material, usually soft connected to the tank.

As a leader in China vibrator motors industry, Shanghai SHANGZHEN vibrator motors co., Ltd can offer you the vibratory motors of vibratory conveyor.